Chromate Conversion Services

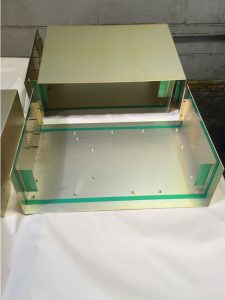

Ace Anodizing’s expert chromate conversion services are highly automated, which gives us the ability to deliver fast turnarounds that meet your demanding production scheduling needs. Our facility houses large rack tanks capable of immersing parts up to 24′ long x 38″ wide x 60″ height and weighing up to 2,500 pounds. Chromate conversion is an inexpensive way to impart increased corrosion resistance and provide a good bonding surface for paint and adhesives to parts such as electronic components, heat sinks, electrical cabinet interiors, or any product fabricated from aluminum and aluminum alloys. An additional benefit is that the parts retain their electrically conductive properties.

Ace Anodizing’s expert chromate conversion services are highly automated, which gives us the ability to deliver fast turnarounds that meet your demanding production scheduling needs. Our facility houses large rack tanks capable of immersing parts up to 24′ long x 38″ wide x 60″ height and weighing up to 2,500 pounds. Chromate conversion is an inexpensive way to impart increased corrosion resistance and provide a good bonding surface for paint and adhesives to parts such as electronic components, heat sinks, electrical cabinet interiors, or any product fabricated from aluminum and aluminum alloys. An additional benefit is that the parts retain their electrically conductive properties.

We offer an RoHS-compliant clear trivalent chromium process that is free from hexavalent chromium and complies with the requirements of MIL-DTL-5541F Class 3.

We also offer the more traditional process for gold and yellow MIL-DTL-5541F Class 1A requirements. Whatever your needs, Ace Anodizing will consult with you to ensure that the right process is selected. Our full service facility also offers a range of post-treatment operations, including painting, powder coating, and anodizing, giving you a single-source solution to your part finishing needs.

To learn more about our chromate conversion services read below, or contact Ace Anodizing today.

Portfolios

- Two Step Anodizing of Aluminum Fabricated Components

- Vacuum Impregnation of an Aluminum Housing for Pump Manufacturing

- Powder Coating of Fabricated Architectural Extruded Aluminum Louvers

- Type II Bright Dip Anodizing of Aluminum Components

- Powder Coating of Heavy Gauge Formed and Welded Steel Tanks

- Powder Coating of Large Diameter Environmental Control System

- Two Step Anodizing of Aluminum Components for the Watercraft & Marine Industry

Chromate Conversion Capabilities

| Chromate Conversion Processes | Immersion |

| Equipment | Rack Tanks |

| Curing | Drying |

| Automation Capabilities | Conveyors Manual |

| Post-Plate Operations | Painting Powder Coating Anodizing Plating |

| Substrate | Aluminum Castings Aluminum Alloys |

| Colors | Gold/Yellow Class 1 Clear (RoHS) Class 3 Light Iridescent |

| Types | Alodine Iridite Yellow Chromate |

| Plating Characteristics | Self-Healing Undercoat Electrically Conductive |

| Benefits | Increased Corrosion Resistance Good Bonding Surface for Paint & Adhesives Inexpensive |

| Part Length | Up to 24 ft |

| Part Width | Up to 38 in |

| Part Height | Up to 60 in |

| Part Weight | Up to 2500 lb |

| Testing Ability | Visual |

| Additional Services | Masking (Stock and Custom) Tooling Consulting Design Assistance Sampling On-Site Tooling Fabrication Brushing Polishing Blasting Silk Screening Pad Printing Laser Part Marking Proto Type Sample processing Pick Up and Delivery In House Tooling Fabrication Lab |

| Production Volume | Prototype to Production |

| Typical Lead Time | 3 to 7 days Rush Services Available |

Additional Information

| Intended Application | Fabrications Extrusions Die Castings Heat Sinks Electronic Components Interior Electrical Cabinets |

| Industry Focus | Medical Aerospace Commercial Recreational Industrial Electrical |

| Industry Standards | ISO 9001:2015 Certified AAMA 2603, 2604, & 2605 Certified TCP WEEE RoHS MIL-DTL-5541F Class 1A MIL-DTL-5541F Class 3 |

| File Formats |