[fusion_builder_container background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_repeat=”no-repeat” background_position=”left top” video_aspect_ratio=”16:9″ video_mute=”yes” video_loop=”yes” fade=”no” border_size=”0px” border_style=”solid” padding_top=”20″ padding_bottom=”10″ hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”no”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none” last=”no” hover_type=”none” link=”” border_position=”all”][fusion_title size=”2″ content_align=”left” style_type=”none”]

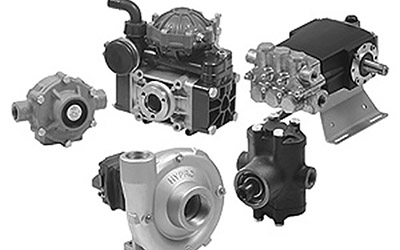

Vacuum Impregnation of Die Cast Aluminum Housing for a Pump Manufacturer

[/fusion_title][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_repeat=”no-repeat” background_position=”left top” video_aspect_ratio=”16:9″ video_mute=”yes” video_loop=”yes” fade=”no” border_size=”0px” border_style=”solid” padding_top=”0″ padding_bottom=”0″ hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”no”][fusion_builder_row][fusion_builder_column type=”1_3″ layout=”1_3″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” min_height=””][fusion_imageframe style_type=”dropshadow” hover_type=”zoomin” bordersize=”1px” bordercolor=”#adadad” borderradius=”0″ align=”center” lightbox=”yes” lightbox_image=”https://www.acemetalfinishing.com/wp-content/uploads/2016/11/impreg_1_lg.jpg” alt=”Vacuum Impregnation” linktarget=”_self” hide_on_mobile=”no” animation_direction=”down” animation_speed=”0.1″]  [/fusion_imageframe][fusion_text]

[/fusion_imageframe][fusion_text]

Click to Enlarge

[/fusion_text][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_3″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” min_height=””][fusion_imageframe style_type=”dropshadow” hover_type=”zoomin” bordersize=”1px” bordercolor=”#adadad” borderradius=”0″ align=”center” lightbox=”yes” lightbox_image=”https://www.acemetalfinishing.com/wp-content/uploads/2016/11/impreg_2_lg.jpg” alt=”Vacuum Impregnation Services” linktarget=”_self” hide_on_mobile=”no” animation_direction=”down” animation_speed=”0.1″]  [/fusion_imageframe][fusion_text]

[/fusion_imageframe][fusion_text]

Click to Enlarge

[/fusion_text][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_3″ last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” min_height=””][fusion_imageframe style_type=”dropshadow” hover_type=”zoomin” bordersize=”1px” bordercolor=”#adadad” borderradius=”0″ align=”center” lightbox=”yes” lightbox_image=”https://www.acemetalfinishing.com/wp-content/uploads/2016/11/impreg_3_lg.jpg” alt=”Vacuum Impregnation Manufacturing” linktarget=”_self” hide_on_mobile=”no” animation_direction=”down” animation_speed=”0.1″]  [/fusion_imageframe][fusion_text]

[/fusion_imageframe][fusion_text]

Click to Enlarge

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_repeat=”no-repeat” background_position=”left top” video_aspect_ratio=”16:9″ video_mute=”yes” video_loop=”yes” fade=”no” border_size=”0px” border_style=”solid” padding_top=”0″ padding_bottom=”0″ hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”no”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none” last=”no” hover_type=”none” link=”” border_position=”all”][fusion_text]A high volume pump manufacturer required vacuum impregnation of a 380 aluminum, die cast pump. The vacuum impregnation was to provide sealing of micro porosity, and was to be completed after painting and machining, this uncommon order of process required special handling. Custom dividers had to be installed in the vessel to avoid damaging any of the finished surfaces, and meet the high rate of production required.

The process which had explicit porosity impregnation requirements was to be performed on specific areas which required an air tight seal on the pump and oil side of the casting. Each finished part was placed through thermal curing and UV inspection before being placed in specific customer specified packaging. The customer order for this product consisted of 125,000 parts to be produced annually, or 500 per day. We not only met all of the customers’ requirements for quality and production but also provided them with next day delivery to keep their operation stocked at all times.

To learn more about this project, see the table below or contact us directly.

[fusion_button link=”https://www.acemetalfinishing.com/request-for-quote/” color=”default” size=”medium” stretch=”” type=”flat” shape=”square” target=”_self” title=”” gradient_colors=”|” gradient_hover_colors=”|” accent_color=”” accent_hover_color=”” bevel_color=”” border_width=”1px” icon=”” icon_divider=”yes” icon_position=”left” modal=”” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” alignment=”center” class=”” id=””]Request a Quote/Information[/fusion_button]

Highlights of this Precision Vacuum Impregnation Project

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_repeat=”no-repeat” background_position=”left top” video_aspect_ratio=”16:9″ video_mute=”yes” video_loop=”yes” fade=”no” border_size=”0px” border_style=”solid” padding_top=”20″ padding_bottom=”0″ hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”no”][fusion_builder_row][fusion_builder_column type=”1_5″ layout=”1_5″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” element_content=”” min_height=””][/fusion_builder_column][fusion_builder_column type=”3_5″ layout=”3_5″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” min_height=””][fusion_code]Jmx0O3RhYmxlIGNsYXNzPSZxdW90O3NwZWNpZmljYXRpb25zJnF1b3Q7IGJvcmRlcj0mcXVvdDsxJnF1b3Q7IHdpZHRoPSZxdW90OzEwMCUmcXVvdDsgY2VsbHNwYWNpbmc9JnF1b3Q7NiZxdW90OyBjZWxscGFkZGluZz0mcXVvdDswJnF1b3Q7IGJnY29sb3I9JnF1b3Q7I2Q4ZDhkOCZxdW90OyZndDsKJmx0O3Rib2R5Jmd0OwombHQ7dHImZ3Q7CiZsdDt0ZCB3aWR0aD0mcXVvdDs0MCUmcXVvdDsmZ3Q7UHJvZHVjdCBEZXNjcmlwdGlvbiZsdDsvdGQmZ3Q7CiAgICAgICZsdDt0ZCZndDtBbHVtaW51bSBEaWUgQ2FzdGluZ3MmbHQ7L3RkJmd0OwogICAgJmx0Oy90ciZndDsKICAgICZsdDt0ciZndDsKICAgICAgJmx0O3RkJmd0O1ZhY3V1bSBJbXByZWduYXRpb24gQ2FwYWJpbGl0aWVzIEFwcGxpZWQvUHJvY2Vzc2VzJmx0Oy90ZCZndDsKICAgICAgJmx0O3RkJmd0OyZsdDtzdHJvbmcmZ3Q7UHJpbWFyeTombHQ7L3N0cm9uZyZndDsmbHQ7YnImZ3Q7CiAgICAgICAgVmFjdXVtIEltcHJlZ25hdGlvbgogICAgICAgICZsdDt1bCZndDsKICAgICAgICAgICZsdDtsaSZndDtDYXN0ICZsdDsvbGkmZ3Q7CiAgICAgICAgICAmbHQ7bGkmZ3Q7VHJpbSAmbHQ7L2xpJmd0OwogICAgICAgICAgJmx0O2xpJmd0O3doZWVsYWJyYXRlICZsdDsvbGkmZ3Q7CiAgICAgICAgICAmbHQ7bGkmZ3Q7UGFpbnQgJmx0Oy9saSZndDsKICAgICAgICAgICZsdDtsaSZndDtNYWNoaW5lICZsdDsvbGkmZ3Q7CiAgICAgICAgICAmbHQ7bGkmZ3Q7VmFjdXVtIEltcHJlZ25hdGlvbiAmbHQ7L2xpJmd0OwogICAgICAgICZsdDsvdWwmZ3Q7CiAgICAgICAgJmx0O3N0cm9uZyZndDtTZWNvbmRhcnk6Jmx0Oy9zdHJvbmcmZ3Q7Jmx0O2JyJmd0OwogICAgICAgIFRoZXJtYWwgQ3VyaW5nJmx0O2JyJmd0OwogICAgICAgICZsdDticiZndDsKICAgICAgICBQYWNrYWdpbmcKICAgICAgICAmbHQ7dWwmZ3Q7CiAgICAgICAgICAmbHQ7bGkmZ3Q7Q2VsbCBQYWNrIGluIFJldHVybmFibGUgQ2VsbCBEaXZpZGVkIFBhY2thZ2luZyBGcmVlIG9mIERlYnJpcyBhbmQgQW55IENvbnRhaW5tZW50cyAmbHQ7L2xpJmd0OwogICAgICAgICZsdDsvdWwmZ3Q7Jmx0Oy90ZCZndDsKICAgICZsdDsvdHImZ3Q7CiAgICAmbHQ7dHImZ3Q7CiAgICAgICZsdDt0ZCZndDtPdmVyYWxsIFBhcnQgRGltZW5zaW9ucyZsdDsvdGQmZ3Q7CiAgICAgICZsdDt0ZCZndDtMZW5ndGg6IDguODYmcXVvdDsmbHQ7YnImZ3Q7CiAgICAgICAgV2lkdGg6IDUuMzMmcXVvdDsmbHQ7YnImZ3Q7CiAgICAgICAgVGhpY2tuZXNzOiAxLjM0JnF1b3Q7Jmx0Oy90ZCZndDsKICAgICZsdDsvdHImZ3Q7CiAgICAmbHQ7dHImZ3Q7CiAgICAgICZsdDt0ZCZndDtUb2xlcmFuY2VzJmx0Oy90ZCZndDsKICAgICAgJmx0O3RkJmd0O0FpciB0aWdodG5lc3Mgb2YgcHVtcCBzaWRlL0FpciB0aWdodG5lc3Mgb2Ygb2lsIHNlYWwgc2lkZSZsdDsvdGQmZ3Q7CiAgICAmbHQ7L3RyJmd0OwogICAgJmx0O3RyJmd0OwogICAgICAmbHQ7dGQmZ3Q7TWF0ZXJpYWwgQ29hdGVkJmx0Oy90ZCZndDsKICAgICAgJmx0O3RkJmd0O0EgMzgwIEFsdW1pbnVtIERpZSBDYXN0aW5nJmx0Oy90ZCZndDsKICAgICZsdDsvdHImZ3Q7CiAgICAmbHQ7dHImZ3Q7CiAgICAgICZsdDt0ZCZndDtSZXNpc3RhbmNlcyZsdDsvdGQmZ3Q7CiAgICAgICZsdDt0ZCZndDtTdXJmYWNlIE11c3QgQmUgU2VhbGVkIHRvIEFpciBUaWdodG5lc3MgUGVyIFByaW50IG9uIE9pbCBhbmQgQWlyc2lkZSZsdDsvdGQmZ3Q7CiAgICAmbHQ7L3RyJmd0OwogICAgJmx0O3RyJmd0OwogICAgICAmbHQ7dGQmZ3Q7RmVhdHVyZXMmbHQ7L3RkJmd0OwogICAgICAmbHQ7dGQmZ3Q7UGFydHMgYXJlIFBhaW50ZWQgUHJpb3IgdG8gVmFjdXVtIEltcHJlZ25hdGlvbiZsdDsvdGQmZ3Q7CiAgICAmbHQ7L3RyJmd0OwogICAgJmx0O3RyJmd0OwogICAgICAmbHQ7dGQmZ3Q7SW4gcHJvY2VzcyB0ZXN0aW5nL2luc3BlY3Rpb24gcGVyZm9ybWVkJmx0Oy90ZCZndDsKICAgICAgJmx0O3RkJmd0O1VWIEluc3BlY3Rpb24mbHQ7YnImZ3Q7CiAgICAgICAgQ292ZXJhZ2UgVGVzdGluZyZsdDsvdGQmZ3Q7CiAgICAmbHQ7L3RyJmd0OwogICAgJmx0O3RyJmd0OwogICAgICAmbHQ7dGQmZ3Q7SW5kdXN0cnkgZm9yIFVzZSZsdDsvdGQmZ3Q7CiAgICAgICZsdDt0ZCZndDtQdW1wIE1hbnVmYWN0dXJpbmcmbHQ7L3RkJmd0OwogICAgJmx0Oy90ciZndDsKICAgICZsdDt0ciZndDsKICAgICAgJmx0O3RkJmd0O1ZvbHVtZSZsdDsvdGQmZ3Q7CiAgICAgICZsdDt0ZCZndDsxMjUsMDAwIFBpZWNlcyBQZXIgWWVhciZsdDticiZndDsKICAgICAgICA1MDAgUGllY2VzIFBlciBEYXkmbHQ7L3RkJmd0OwogICAgJmx0Oy90ciZndDsKICAgICZsdDt0ciZndDsKICAgICAgJmx0O3RkJmd0O0RlbGl2ZXJ5L1R1cm5hcm91bmQgVGltZSZsdDsvdGQmZ3Q7CiAgICAgICZsdDt0ZCZndDtOZXh0IERheS9PdmVybmlnaHQgRGVsaXZlcnkmbHQ7L3RkJmd0OwogICAgJmx0Oy90ciZndDsKICAgICZsdDt0ciZndDsKICAgICAgJmx0O3RkJmd0O0RlbGl2ZXJ5IExvY2F0aW9uJmx0Oy90ZCZndDsKICAgICAgJmx0O3RkJmd0O1dpc2NvbnNpbiAmbHQ7L3RkJmd0OwogICAgJmx0Oy90ciZndDsKICAgICZsdDt0ciZndDsKICAgICAgJmx0O3RkJmd0O1N0YW5kYXJkcyBNZXQmbHQ7L3RkJmd0OwogICAgICAmbHQ7dGQmZ3Q7Um9IUy9FRUxWIENvbXBsaWFudCZsdDticiZndDsKICAgICAgICBNSUwtU1RELTI3NkEmbHQ7YnImZ3Q7CiAgICAgICAgTUlMLVNURC0xNzU2M0MmbHQ7YnImZ3Q7CiAgICAgICAgSVNPIDkwMDE6MjAxNSZsdDsvdGQmZ3Q7CiAgICAmbHQ7L3RyJmd0OwogICAgJmx0O3RyJmd0OwogICAgICAmbHQ7dGQmZ3Q7UHJvZHVjdCBOYW1lJmx0Oy90ZCZndDsKICAgICAgJmx0O3RkJmd0O1B1bXAgSG91c2luZyZsdDsvdGQmZ3Q7CiAgICAmbHQ7L3RyJmd0OwogICZsdDsvdGJvZHkmZ3Q7CiZsdDsvdGFibGUmZ3Q7Cg==[/fusion_code][/fusion_builder_column][fusion_builder_column type=”1_5″ layout=”1_5″ last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” element_content=”” min_height=””][/fusion_builder_column][fusion_builder_column type=”1_4″ layout=”1_4″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” element_content=”” min_height=””][/fusion_builder_column][fusion_builder_column type=”1_4″ layout=”1_4″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” min_height=””][fusion_code]Jmx0O3Agc3R5bGU9JnF1b3Q7dGV4dC1hbGlnbjogY2VudGVyOyZxdW90OyZndDtbZnVzaW9uX2J1dHRvbiBsaW5rPSZxdW90O2h0dHA6Ly93d3cuYWNlbWV0YWxmaW5pc2hpbmcuY29tL3JlcXVlc3QtZm9yLXF1b3RlLyZxdW90OyBjb2xvcj0mcXVvdDtkZWZhdWx0JnF1b3Q7IHNpemU9JnF1b3Q7bWVkaXVtJnF1b3Q7IHN0cmV0Y2g9JnF1b3Q7JnF1b3Q7IHR5cGU9JnF1b3Q7ZmxhdCZxdW90OyBzaGFwZT0mcXVvdDtzcXVhcmUmcXVvdDsgdGFyZ2V0PSZxdW90O19zZWxmJnF1b3Q7IHRpdGxlPSZxdW90OyZxdW90OyBncmFkaWVudF9jb2xvcnM9JnF1b3Q7fCZxdW90OyBncmFkaWVudF9ob3Zlcl9jb2xvcnM9JnF1b3Q7fCZxdW90OyBhY2NlbnRfY29sb3I9JnF1b3Q7JnF1b3Q7IGFjY2VudF9ob3Zlcl9jb2xvcj0mcXVvdDsmcXVvdDsgYmV2ZWxfY29sb3I9JnF1b3Q7JnF1b3Q7IGJvcmRlcl93aWR0aD0mcXVvdDsxcHgmcXVvdDsgaWNvbj0mcXVvdDsmcXVvdDsgaWNvbl9kaXZpZGVyPSZxdW90O3llcyZxdW90OyBpY29uX3Bvc2l0aW9uPSZxdW90O2xlZnQmcXVvdDsgbW9kYWw9JnF1b3Q7JnF1b3Q7IGFuaW1hdGlvbl90eXBlPSZxdW90OzAmcXVvdDsgYW5pbWF0aW9uX2RpcmVjdGlvbj0mcXVvdDtkb3duJnF1b3Q7IGFuaW1hdGlvbl9zcGVlZD0mcXVvdDswLjEmcXVvdDsgYW5pbWF0aW9uX29mZnNldD0mcXVvdDsmcXVvdDsgYWxpZ25tZW50PSZxdW90O2NlbnRlciZxdW90OyBjbGFzcz0mcXVvdDsmcXVvdDsgaWQ9JnF1b3Q7JnF1b3Q7XVJlcXVlc3QgYSBRdW90ZS9JbmZvcm1hdGlvblsvZnVzaW9uX2J1dHRvbl0=[/fusion_code][/fusion_builder_column][fusion_builder_column type=”1_4″ layout=”1_4″ last=”no” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” min_height=””][fusion_code]Jmx0O3Agc3R5bGU9JnF1b3Q7dGV4dC1hbGlnbjogY2VudGVyOyZxdW90OyZndDtbZnVzaW9uX2J1dHRvbiBsaW5rPSZxdW90O2h0dHA6Ly93d3cuYWNlbWV0YWxmaW5pc2hpbmcuY29tL3BvcnRmb2xpb3MvJnF1b3Q7IGNvbG9yPSZxdW90O2RlZmF1bHQmcXVvdDsgc2l6ZT0mcXVvdDttZWRpdW0mcXVvdDsgc3RyZXRjaD0mcXVvdDsmcXVvdDsgdHlwZT0mcXVvdDtmbGF0JnF1b3Q7IHNoYXBlPSZxdW90O3NxdWFyZSZxdW90OyB0YXJnZXQ9JnF1b3Q7X3NlbGYmcXVvdDsgdGl0bGU9JnF1b3Q7JnF1b3Q7IGdyYWRpZW50X2NvbG9ycz0mcXVvdDt8JnF1b3Q7IGdyYWRpZW50X2hvdmVyX2NvbG9ycz0mcXVvdDt8JnF1b3Q7IGFjY2VudF9jb2xvcj0mcXVvdDsmcXVvdDsgYWNjZW50X2hvdmVyX2NvbG9yPSZxdW90OyZxdW90OyBiZXZlbF9jb2xvcj0mcXVvdDsmcXVvdDsgYm9yZGVyX3dpZHRoPSZxdW90OzFweCZxdW90OyBpY29uPSZxdW90OyZxdW90OyBpY29uX2RpdmlkZXI9JnF1b3Q7eWVzJnF1b3Q7IGljb25fcG9zaXRpb249JnF1b3Q7bGVmdCZxdW90OyBtb2RhbD0mcXVvdDsmcXVvdDsgYW5pbWF0aW9uX3R5cGU9JnF1b3Q7MCZxdW90OyBhbmltYXRpb25fZGlyZWN0aW9uPSZxdW90O2Rvd24mcXVvdDsgYW5pbWF0aW9uX3NwZWVkPSZxdW90OzAuMSZxdW90OyBhbmltYXRpb25fb2Zmc2V0PSZxdW90OyZxdW90OyBhbGlnbm1lbnQ9JnF1b3Q7bGVmdCZxdW90OyBjbGFzcz0mcXVvdDsmcXVvdDsgaWQ9JnF1b3Q7JnF1b3Q7XVZpZXcgT3RoZXIgUG9ydGZvbGlvc1svZnVzaW9uX2J1dHRvbl0mbHQ7L3AmZ3Q7[/fusion_code][/fusion_builder_column][fusion_builder_column type=”1_4″ layout=”1_4″ last=”yes” spacing=”yes” center_content=”no” hide_on_mobile=”no” background_color=”” background_image=”” background_repeat=”no-repeat” background_position=”left top” hover_type=”none” link=”” border_position=”all” border_size=”0px” border_color=”” border_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”” animation_speed=”0.1″ animation_offset=”” class=”” id=”” element_content=”” min_height=””][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]